When building a house, most people focus on elevation design, room layout, and interior finishes. However, the true strength of any structure lies beneath the surface in its foundation. A properly designed foundation ensures structural stability, prevents settlement issues, and increases the life of the building.

One of the most practical foundation systems used in residential and commercial construction is the cantilever footing. Especially in urban areas with small or boundary-restricted plots, this type of footing becomes highly useful.

In this detailed guide, we’ll explore everything you need to know about cantilever footing from definition and working principle to design considerations, advantages, disadvantages, and construction steps.

Table of Contents

ToggleWhat Is Cantilever Footing?

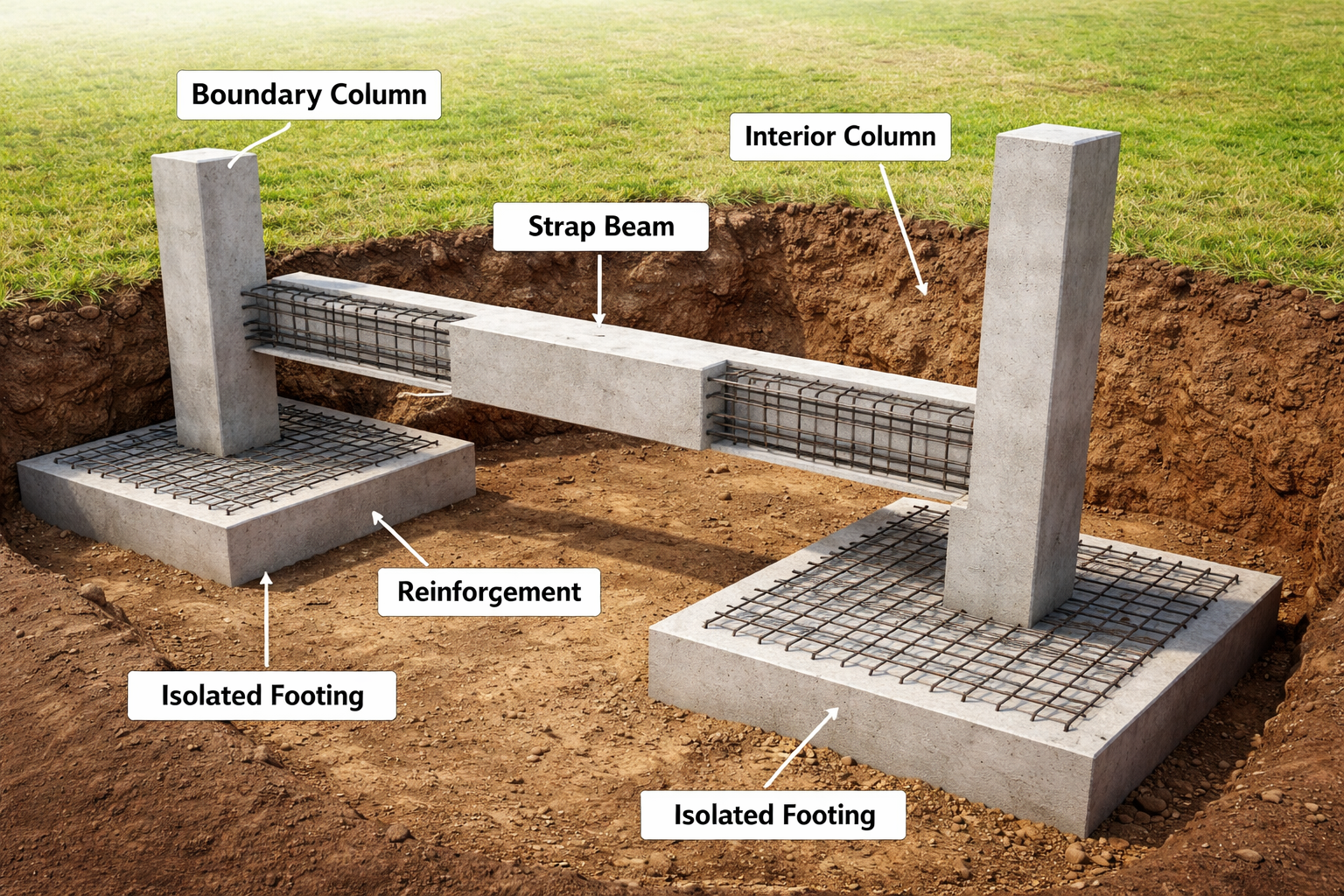

A cantilever footing, also known as a strap footing, is a type of combined foundation system where two isolated footings are connected by a rigid beam called a strap beam.

This beam transfers load from one column to another to balance soil pressure under the footings.

It is mainly used when:

-

A column is located very close to the property boundary

-

The footing cannot be extended beyond the plot line

-

There is eccentric loading

-

Load balancing between columns is required

In simple words, when a column is near the edge of a plot and a normal centered footing is not possible, a cantilever footing helps distribute the load properly without crossing the boundary.

Why Cantilever Footing Is Needed

In densely populated urban areas, residential plots are often small such as 20×40 ft, 25×50 ft, or 30×40 ft plots. When constructing a building on such sites, columns are sometimes positioned very close to the boundary.

In a normal isolated footing:

-

The footing should extend equally on all sides of the column.

-

This keeps soil pressure uniform.

However, when a column is near the boundary:

-

The footing cannot extend outward beyond the property line.

-

This causes eccentric loading.

-

Uneven soil pressure develops.

-

Settlement risk increases.

To solve this issue, engineers connect the edge footing with another interior footing using a strap beam. This connection balances the load and prevents uneven settlement.

Components of Cantilever Footing

A cantilever footing system consists of the following parts:

1. Edge Footing

This is the footing provided under the boundary column. It usually experiences eccentric loading.

2. Interior Footing

This footing is placed under an interior column. It helps balance the load transferred through the strap beam.

3. Strap Beam

The most important component. This reinforced concrete beam connects both footings and transfers bending moments between them.

4. Columns

Columns transfer structural loads (dead load + live load) to the footing.

5. Reinforcement Steel

Steel bars are provided in both footings and strap beam to resist bending and shear forces.

How Cantilever Footing Works

The cantilever footing works on the principle of load transfer and moment balancing.

Here’s how it functions:

-

The boundary column produces an eccentric load because the footing cannot extend outward.

-

The strap beam connects it to the interior footing.

-

The beam transfers part of the moment and load to the interior column.

-

Soil pressure becomes uniform under both footings.

-

Differential settlement is prevented.

The strap beam itself usually does not rest directly on soil. It is designed to remain above ground or lightly supported, so it acts structurally rather than bearing soil pressure.

Where Cantilever Footing Is Used

Cantilever footing is commonly used in:

-

Residential buildings on small plots

-

Row houses

-

Duplex houses

-

Commercial buildings with property line restrictions

-

Structures constructed close to neighboring buildings

-

Buildings with uneven column loads

In cities where plots are compact and every inch matters, this foundation type becomes extremely practical.

Advantages of Cantilever Footing

1. Ideal for Boundary Columns

It allows construction without violating property lines.

2. Prevents Uneven Settlement

Load balancing reduces differential settlement.

3. Structurally Efficient

Transfers bending moments effectively.

4. Economical for Restricted Sites

Avoids constructing oversized footings.

5. Suitable for Medium Soil Conditions

Works well where soil bearing capacity is moderate.

6. Maintains Structural Alignment

Ensures building remains stable and vertical.

Disadvantages of Cantilever Footing

While beneficial, it has certain limitations:

-

Requires detailed structural calculations

-

More complex than isolated footing

-

Needs precise reinforcement placement

-

Not suitable for very weak or highly compressible soil

-

Construction supervision must be strict

Improper design or poor workmanship can lead to cracking or structural imbalance.

Cantilever Footing vs Combined Footing

Understanding the difference is important before choosing the right foundation.

| Feature | Cantilever Footing | Combined Footing |

|---|---|---|

| Structure | Two separate footings | Single large footing |

| Connection | Connected by strap beam | No strap beam |

| Use Case | Boundary restriction | Columns close together |

| Soil Pressure Control | Via moment transfer | Via shared base |

| Construction | Slightly complex | Relatively simple |

If both columns are close together and space allows, combined footing may be used.

If one column is near the boundary, cantilever footing is the better option.

Design Considerations for Cantilever Footing

Before finalizing this foundation type, engineers analyze several factors:

1. Soil Bearing Capacity (SBC)

Soil test is essential to determine allowable pressure.

2. Column Load

Dead load + live load calculations are required.

3. Distance Between Columns

This affects beam design and moment transfer.

4. Bending Moment

Strap beam must be designed to resist bending forces.

5. Shear Strength

Footing thickness must resist shear stresses.

6. Settlement Analysis

Uniform settlement must be ensured.

Without proper design calculations, the system may fail.

Step-by-Step Construction Process

Step 1: Site Marking

Mark column and footing locations as per structural drawings.

Step 2: Excavation

Excavate pits to required depth.

Step 3: PCC Layer

Lay Plain Cement Concrete (PCC) for leveling.

Step 4: Reinforcement Work

Place steel bars in footing and strap beam according to design.

Step 5: Shuttering

Install formwork for footings and beam.

Step 6: Concrete Pouring

Pour concrete and compact properly using vibrators.

Step 7: Curing

Cure the concrete for at least 7–14 days.

Proper curing ensures strength development.

Common Mistakes to Avoid

-

Skipping soil testing

-

Undersized strap beam

-

Poor reinforcement detailing

-

Allowing strap beam to bear soil load unintentionally

-

Inadequate curing

Even small mistakes in foundation construction can lead to major structural issues later.

Is Cantilever Footing Suitable for Residential Homes?

Yes, it is widely used in residential construction, especially in urban areas.

However, it must be:

-

Designed by a structural engineer

-

Based on soil test report

-

Executed under professional supervision

Many modern duplex and G+1 homes use this foundation safely and effectively.

Cost of Cantilever Footing

The cost depends on:

-

Depth of foundation

-

Concrete grade

-

Steel quantity

-

Soil condition

-

Location

It is generally slightly more expensive than isolated footing due to the strap beam.

However, it is far more economical than fixing foundation failures later.

When Should You Choose Cantilever Footing?

Choose cantilever footing if:

-

One column is very close to boundary

-

You cannot extend footing outward

-

Unequal load balancing is required

-

Structural stability is a concern

Avoid it if:

-

Soil is extremely weak

-

Columns are extremely far apart

-

Space allows simpler foundation options

Wrapping Up

Cantilever footing is a smart structural solution for modern construction challenges, especially in compact urban plots. It allows proper load distribution without crossing property boundaries and ensures balanced soil pressure under columns.

While it may appear simple, its design involves detailed structural calculations. The strap beam plays a critical role in transferring moments and maintaining equilibrium.

Before selecting any foundation type, always:

-

Conduct soil testing

-

Consult a qualified structural engineer

-

Follow proper reinforcement detailing

-

Ensure high-quality construction

Remember, the foundation is not visible once construction is complete but it determines the safety, durability, and lifespan of your building.

Investing in the right foundation system today ensures structural peace of mind for decades to come.

Planning to build your home with a structurally safe foundation?

At SmartScale House Design, we don’t just design beautiful homes we ensure they are structurally strong from the ground up. Our expert architects and structural engineers provide:

-

Customized house plans

-

Soil-based foundation recommendations

-

Structural drawings with safe footing design

-

3D elevation and working drawings

-

Vastu-compliant layouts

Whether your plot has boundary restrictions or requires specialized foundations like cantilever footing, we design smart, safe, and cost-effective solutions.

Start your home design journey today with SmartScale House Design.